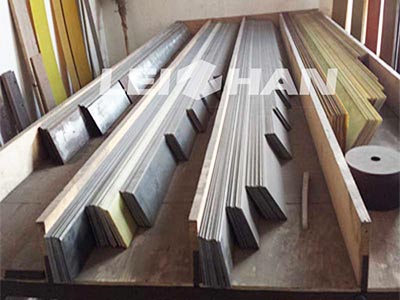

Paper Machine Spare Parts Doctor Blade

In high-speed toilet paper production, every micron of deviation may affect the delivery of tens of millions of orders. Our wrinkling doctor blade and paper breaking doctor blade, with military-grade manufacturing standards and intelligent control, have become the trusted choice of large paper companies for foreign customers!

Why choose our doctor blade?

1. Ultra-long life design

The SUS304 fixture resists chemical erosion, and the Q235A body undergoes triple surface treatment, with a lifespan twice that of conventional products, and is suitable for high temperature and high humidity environments.

2. Dynamic pressure adaptation

The wrinkling doctor blade uses airbag pressure compensation technology to adjust the contact surface pressure in real time, and can maintain the best wrinkling rate (CRT value is stable at 2.8-3.2) even if the base paper tension fluctuates.

The paper breaking doctor blade is equipped with a high-precision cylinder, which completes pressure switching within 0.1 seconds, with a slitting error of <0.5mm and a scrap rate reduced to less than 0.3%.

3. Modular maintenance, saving time and effort

The tool holder and drive unit adopt a quick-release design, which shortens the replacement time to 30 minutes and supports online maintenance without shutting down the entire line.

Leizhan Machinery can optimize the design of doctor blade according to the paper type and daily output produced by customers. The maintenance cycle is extended by 30%, significantly reducing downtime costs. Consult now for more details. Contact: leizhanworld@gmail.com