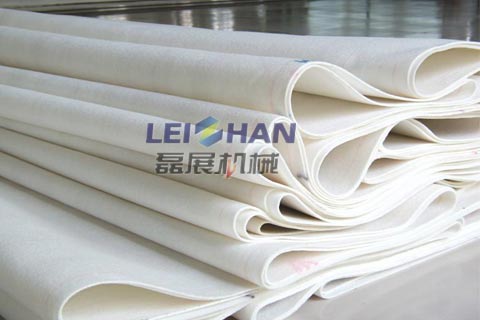

High-quality Paper Machine Felts

In practical paper production, it is important to prioritize the use of high-quality felts. Along suitable options, performing regular washing, and conducting thorough inspections before usage, efforts should be made to minimize potential faults during operation. This article primarily focuses on addressing the pressure loss of felts.

Main reasons:

Excessive pulp accumulation on the felt loop, leading to its entry into the pressing zone due to maintenance or parts dislodging from the frame;

Debris such as pulp or felt balls falling onto the frame and entering the felt loop, along with hard particles brought in by the mesh;

Significant irregularities in the pressure exerted by the press roll;

Felt damage resulting from welding.

It is recommended to replace the felt if there are large holes present. However, if the hole is small and the overall quality of the felt is still intact temporary measures such as sewing can be undertaken to ensure uninterrupted production. If you are in need of high-quality felt, feel free to reach out to us at leizhanworld@gmail.com